In the bustling environment of a workshop, where every project brings its own set of challenges and rewards, the air quality can often be taken for granted. Yet, the presence of dust, chemicals, and other contaminants can pose serious health risks, compromising the safety and well-being of everyone inside the building. These systems play a crucial role in maintaining a clean and healthy workspace by efficiently removing these hazardous particles from the air. This blog explores the importance of implementing the best air filtration system for workshops, ensuring a safer and more productive environment for all.

The Need for Air Filtration in Workshops

Workshops, whether they cater to woodworking, metalworking, or other crafts, generate a significant amount of particulates and vapors that can be harmful if inhaled. Common contaminants such as wood dust, metal filings, and chemical fumes not only degrade the quality of the air but also pose severe health risks to individuals exposed to them regularly.

Health Risks in the Workshop

Exposure to fine dust particles and chemical vapors can lead to a range of health issues, from temporary discomfort such as eye irritation and respiratory problems to more severe long-term conditions like chronic bronchitis or even cancer. For instance, wood dust is a well-known carcinogen, and continuous exposure without proper air filtration can have dire consequences.

The quality of air inside of the building is critical for health and safety. Accumulated dust and fumes can become combustible under certain conditions, posing a fire risk. An effective workshop air filtration system serves multiple purposes: it significantly reduces the concentration of airborne contaminants, minimizes health risks, and enhances overall safety by mitigating potential fire hazards.

Understanding Air Filtration Systems

Air filtration systems are essential tools for maintaining a safe and healthy workshop environment. These systems are designed to capture and remove airborne particles and contaminants through a series of filters, ensuring that the air inside the building remains clean and safe for breathing.

How Air Filtration Systems Work

Air filtration systems typically consist of several components that work together to clean the air. The air is first drawn into the unit, where it passes through a pre-filter that captures larger particles such as dust and debris. The air then moves through finer filters, like HEPA filters, which are designed to trap smaller particles down to 0.3 microns in size with a 99.97% efficiency. Some systems also incorporate activated carbon filters, which are effective in removing gases and odors from solvents, paints, and other chemicals commonly used in workshops.

Types of Air Filtration Systems

- HEPA Air Filtration Systems:Ideal for capturing fine particulates like dust and pollen, making them suitable for environments with high particulate emissions such as woodworking or stone carving workshops.

- Activated Carbon Systems:Best for workshops that frequently use chemicals and solvents, as these systems are effective at absorbing odors and volatile organic compounds.

- Electrostatic Air Cleaners:Use an electrical charge to attract and trap charged particles and are particularly effective in environments where metal work is performed.

Choosing the right type of air filtration system depends on the specific needs of the workshop, including the types of contaminants commonly present and the volume of air that needs to be processed to maintain safety standards.

Choosing the Best Air Filtration System for Workshops

Selecting the most effective air filtration system for your workshop involves considering several key factors to ensure that the system can adequately handle the specific types of contaminants generated within your workspace.

Key Features to Consider

- Air Flow Rate: The system should have a sufficient air flow rate, typically measured in cubic feet per minute (CFM), to circulate the entire volume of air in the workshop multiple times per hour.

- Filter Efficiency:Look for systems with high-efficiency particulate air (HEPA) filters that can capture 99.97% of particles as small as 0.3 microns.

- Size and Portability: Depending on the size of your workshop and the layout, you might need a larger, more permanent installation or a smaller, portable unit that can be moved as needed.

Installation Considerations

- Placement: Position air scrubbers strategically around the workshop to target areas where contaminants are most concentrated. Ensure that the system's intake and exhaust areas are not obstructed to maximize efficiency.

- Maintenance Accessibility: Choose a system that is easy to maintain. Filters will need to be checked and replaced regularly to keep the system functioning properly, so ease of access to filters is crucial.

By understanding the specific needs of your workshop and carefully selecting an air filtration system that meets these requirements, you can significantly improve the indoor air quality and safety of your workspace. Learn more about choosing the best air filtration system for a workshop depending on size.

Section 4: Benefits of Installing an Air Filtration System Inside the Building

Investing in a high-quality air filtration system offers numerous benefits that extend beyond just maintaining regulatory compliance for air quality. These systems play a critical role in ensuring a safe and conducive work environment.

Improved Health and Safety

Continuous exposure to particulate matter and chemical vapors can lead to serious health issues. An effective air filtration system reduces these risks significantly, contributing to the overall well-being of everyone in the workshop. Cleaner air means fewer health-related absences and a more energetic workforce.

Enhanced Work Efficiency

A clean-air environment can enhance cognitive and physical performance. Workers in a workshop with high-quality air are likely to experience less fatigue and more focus, leading to higher productivity and better quality of workmanship.

Protection of Equipment

Dust and other airborne particles can damage precision tools and machinery over time, leading to costly repairs and maintenance. Air filtration systems help protect these investments by keeping the air clean and free of harmful debris.

Installation and Maintenance of Air Filtration Systems

To maximize the effectiveness of an air filtration system, proper installation and regular maintenance are essential. Here’s how you can ensure your system operates at peak efficiency:

Installation Tips

- Consult Professionals: It’s advisable to work with professionals who can assess your specific needs and recommend the best system layout.

- Optimal Placement: Install the air filtration units in locations where contaminants are most likely generated but ensure they do not interfere with workspace operations.

Maintenance Best Practices

- Regular Filter Replacement:Adhere to the manufacturer’s guidelines for filter changes. Regular replacement of filters ensures the system continues to function effectively.

- Scheduled Inspections: Set up a regular inspection schedule to check for any issues with the system’s performance. Early detection of problems can prevent more significant issues down the line.

- Cleaning and Care:Keep the external parts of the unit clean from dust and debris to avoid any additional strain on the system.

Conclusion

Implementing the best air filtration system for workshop safety is not just a regulatory necessity but a critical investment in health, safety, and operational efficiency. By choosing the right system and ensuring it is maintained correctly, you can create a safer, healthier, and more productive working environment. Check out this latest comparison on Air Purifiers for a workshop.

Get the Best Air Filtration System for Workshop Safety

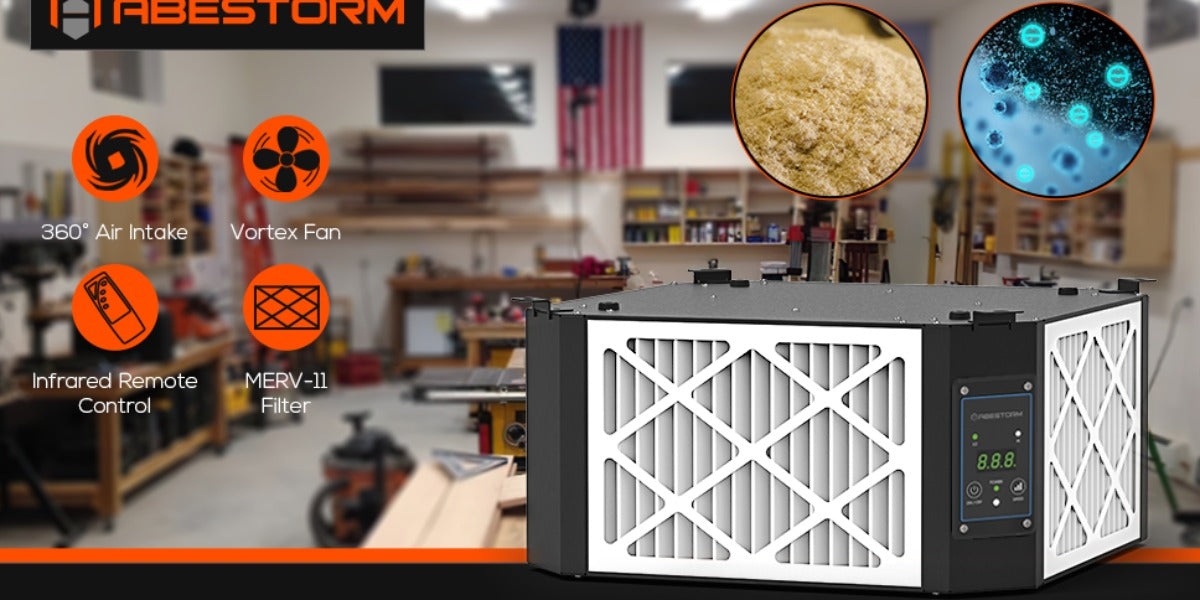

Ready to enhance safety and productivity in your workshop with a top-tier air filtration system? Visit Abestorm.com to explore our range of air filtration systems designed to meet the unique demands of any workshop environment. Don’t compromise on health and safety—ensure your workspace is equipped with the best air filtration technology available today.

Shop For Dehumidifier